17 Pulverbeschichtungsgeräte

Analoges Steuergerät: Pro

Digitales Steuergerät: Master

- Schnellreinigungsfunktion

Pumpenförderung

Becherpistole / Kofferset

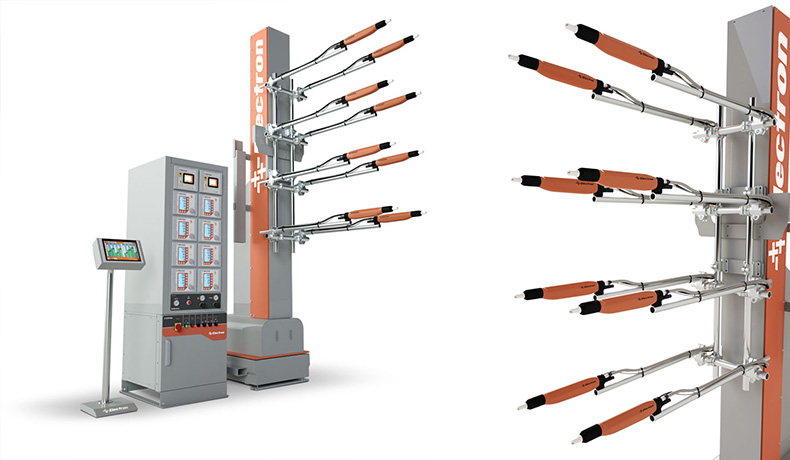

Automatisch

17 Pulverbeschichtungsgeräte

Fernbedienung über Sprühpistole

Präzise Corona Aufladung

Pulversprühmenge unter Kontrolle

50 Beschichtungsrezepte möglich

Farbwechsel bequem und schnell

•Voltage Multiplier System bearbeitet Rückkopplungssignale

•Automatische Regelung der Aufladung (PCC)

PCC = Precise Charge Control

•Maximaler Nutzkomfort auch bei Langzeitbetrieb mit 510 Gramm

•Sicherer spezieller PUR-Mantelkabel

•Schneller Schlauch / Farbwechsel

•Einfache Reinigung

•ATEX II 2 D, IP64 Schutzart

Welches Pulverbeschichtungsgerät ?

oder

oder  ?

?

Wieso das doppelte ausgeben, wenn es genauso hochqualitative Ergebnisse liefert ? Wo werden die Electron Pulvergeräte hergestellt?

Antwort: Komponenten aus der Schweiz, Deutschland und Japan. Die Herstellung erfolgt in der Türkei. Es ist ein 100% türkisches Produkt.

Verpulvern Sie kein Geld ! Beschichten Sie wie ein Profi.

Weltmarke Electron ist aktiv vertreten in 47 Ländern

Komponenten aus der Schweiz, Deutschland und Japan.

Vergleichstabelle Pulverbeschichtungspistolen

Was sind die Preise für Electron E-coat Pulverpistolen? Wieviel kosten die wirklich?

| Hersteller |

|

|

|

|

|---|---|---|---|---|

| Listenpreis Netto | 2.100 € | 5.500 € | 6.900 € | 6.900 € |

| 2. Ersatzpistole | 1.250 € | 2.500 € | 2.500 € | 2.500 € |

| Ersatzteile Kosten | fair | teuer | teuer | überteuert |

| Qualität Verschleissteile | gut - sehr gut | sehr gut | sehr gut | sehr gut |

| Verschleissteile 6 Monate | 515 € | 980 € | 980 € | 1.100 € |

| Verschleissteile 4,5 Jahre | 2.318 € | 4.410 € | 4.410 € | 4.950 € |

| Gesamt inkl. Vers.teile 5Jahre | 6.283 € | 13.390 € | 14.790 € | 15.450 € |

| Beschichtungsergebnisse | sehr gut | gut | sehr gut | sehr gut |

| Bauteile Herkunft | Türkei | kA | kA | kA |

| Wartung und Service | schnell unkompliziert | kA | kA | kA |

| Pumpe / Dichtstrom | ja, optional | kA | ja, optional | kA |

| Schnellwechsel Spülmodul | ja | kA | kA | ja |

Rollwagen

Master M mit Rütteltisch

Pro H mit Behälter

Flachteile

Ausgezeichnete Elektrostatik spart Pulvermenge

Komplizierte Formen

Schnelle Einstellung per Fernbedienung

Applikation von Beschichtungspulver

Handbeschichtungspistolen

Coronaring + Schnellreinigung, automatische Regulierung

- Perfekte Ergebnisse bei gleichmäßiger Schichtdicke

- Schnelle Farbwechsel

- Benutzerfreundliches Panel

17 Industriemodelle

Shop - Jetzt online zu Aktionspreisen kaufen

Shop - Zubehör & Ersatzteile

Die Pulverbeschichtung ist eine beliebte Veredelungstechnik, bei der ein trockenes Pulver auf eine Oberfläche aufgebracht wird. Das Pulver wird dann durch Einbrennen gehärtet und bildet eine harte, dauerhafte Beschichtung. Pulverbeschichtungspistolen sind für dieses Verfahren unverzichtbar, da sie ein präzises und gleichmäßiges Auftragen des Pulvers ermöglichen.

Bei der Auswahl einer Pulverbeschichtungspistole sind mehrere wichtige Faktoren zu berücksichtigen. Dazu gehören die Art der Pistole, das Pulverzufuhrsystem, das Steuersystem sowie die Gesamtqualität und Haltbarkeit der Pistole.

Es gibt zwei Haupttypen von Pulverbeschichtungspistolen: Corona und Tribo. Korona-Pistolen verwenden eine elektrostatische Ladung, um das Pulver auf die zu beschichtende Oberfläche zu bringen. Tribo-Pistolen hingegen laden die Pulverpartikel durch Reibung auf. Jeder Typ hat seine eigenen Vor- und Nachteile, daher ist es wichtig, sorgfältig abzuwägen, welcher Typ am besten für Ihre Bedürfnisse geeignet ist.

Das Pulverzufuhrsystem ist ein weiterer wichtiger Aspekt. Dabei geht es darum, wie das Pulver in die Pistole und auf die zu beschichtende Oberfläche zugeführt wird. Einige Pistolen arbeiten mit einem Wirbelschichtsystem, andere mit einem Kastenförderer oder einem Trichter. Jedes System hat seine eigenen Vor- und Nachteile, so dass es wichtig ist, ein System zu wählen, das für Ihre speziellen Anforderungen geeignet ist.

Katalog Pulverbeschichtungsgeräte

Auch das Steuerungssystem ist ein wichtiger Faktor, den es zu berücksichtigen gilt. Damit ist gemeint, wie die Pistole bedient wird und wie die verschiedenen Einstellungen vorgenommen werden können. Einige Pistolen verfügen über einfache Bedienelemente mit nur wenigen Einstellungen, während andere über fortschrittlichere Bedienelemente mit vielen verschiedenen Optionen verfügen. Es ist wichtig, eine Pistole zu wählen, deren Steuerung einfach zu bedienen ist und präzise Einstellungen ermöglicht.

Schließlich ist es wichtig, auf die Gesamtqualität und Haltbarkeit der Pistole zu achten. Ein hochwertiges Pulverbeschichtungsgerät ist gut gebaut und hält dem regelmäßigen Gebrauch stand, ohne dass es kaputt geht oder Fehlfunktionen aufweist. Es ist auch wichtig, eine Pistole von einem renommierten Hersteller zu wählen, der eine gute Erfolgsbilanz bei der Herstellung zuverlässiger und langlebiger Produkte hat.

Zusammenfassend lässt sich sagen, dass bei der Wahl einer Pulverbeschichtungspistole sorgfältig auf den Pistolentyp, das Pulverzufuhrsystem, das Steuersystem und die Gesamtqualität und Haltbarkeit der Pistole geachtet werden muss. Wenn Sie diese Faktoren berücksichtigen, können Sie eine Pistole wählen, die Ihren Anforderungen entspricht und über Jahre hinweg zuverlässig arbeitet.