Turnkey painting booths

In all dimensions / variations

See also: NFZ Truck Industry Special Dimensions Multifunctional Workstations

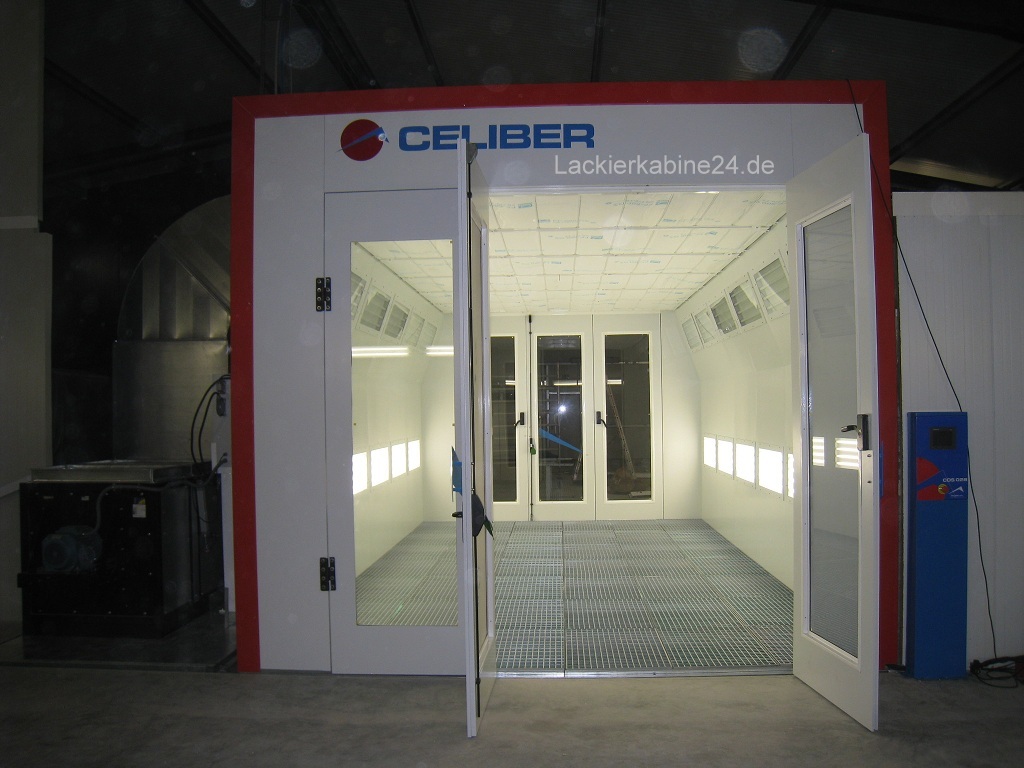

The paint booth !

How does a painting centre work?

Celiber

High quality 100% European production according to CE EN 13355:2004+A1:2009

5 Standard features

5 Standard features

Energy-saving gas-surface burner

Automatic air volume control

User-friendly high-quality digital control

Higher net air power

Patented 19° walls for clean air flow

Painting workshop

Cabin variants - All variants available

Please contact us !

Car paint shop

Transit cabin

NFZ painting system with crane

Car painting cabin with storage room

Preparatory site

Smart Repair

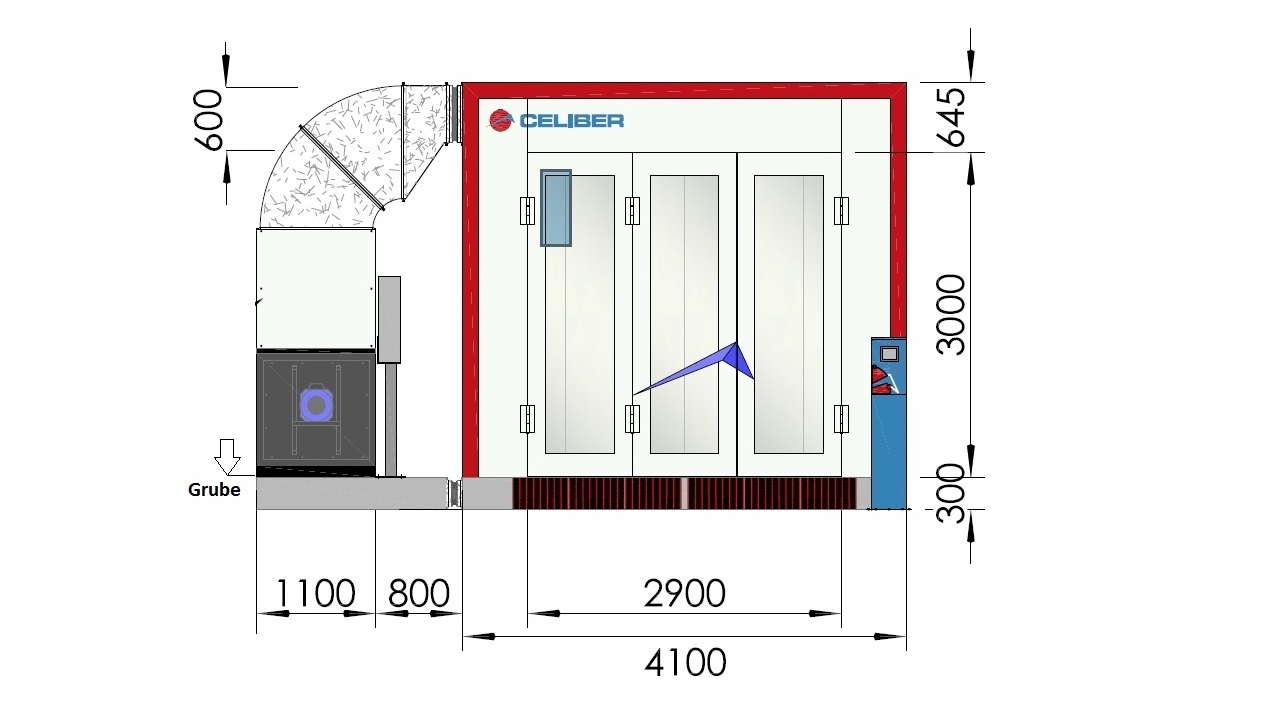

Dimensions indoor LxWxH [m]

Small parts: 3.4 x 2.4 x 2.5 or 5 x 4 x 3

Car: 7x4x3 or in length: 6,6 | 7.7 | 8

Minibus: 9x4.5x3.5 or special dimensions

Unit on the side requires 4 x 2 m of space including maintenance corridor. It can also be set up behind or above the cabin.

Setting up: (picture left to right)

- On concrete slab with a 65cm deep on-site pit with steel beams

- In the ground sunk 29.5cm deep, substructure 30cm is supplied (also 40cm possible)

- With complete ramp 195cm long, substructure 30cm high

- Inner ramp, pneumatically movable or immobile

Sketch

Assembly / construction of a painting booth

Celiber Combined painting and drying systems car / car / car

Mannheim

Mercedes Madrid

Nuremberg

Stuttgart

Nuremberg

Osnabrück

Paris Renault

Stuttgart2

Perfect design

In technology and form

Technology

Energy Saving - Control - Air Performance

Energy saving

Novelty: insulating reflective glasses

60mm thick panels with 150kg/m3 pressed rock wool

Bright LED Lighting

In combination with a paint mixing room

• Components (KWT optional)

• approx. 20% - frequency inverter for 3 air volumes

• approx. 25% - Time and energy - Gas surface burner

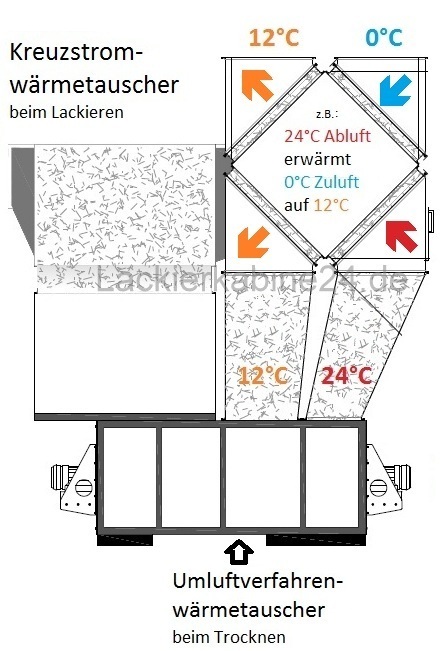

• approx. 50% - Aluminum Cross Current HeatExchangeer

(descriptions below)

Control - leaves nothing to be desired

1- Analog

2- Digital / Touchscreen

3- Touchscreen with PLC computer control and remote maintenance

(Control consumption costs)

Frequency controller (automatic) for three speed levels:

Eco

Painting 1 (70-80%)

Painting 2 (full load)

Painting with 12kW power requirement

Switches to save mode when certain time is not painted

Benefits with PLC

PLC = Programmable logic controller (aucn. PLC)

Gentle motor start-up

Intermediate drying as well as any programs

Modulating burner

Safety monitoring of all components

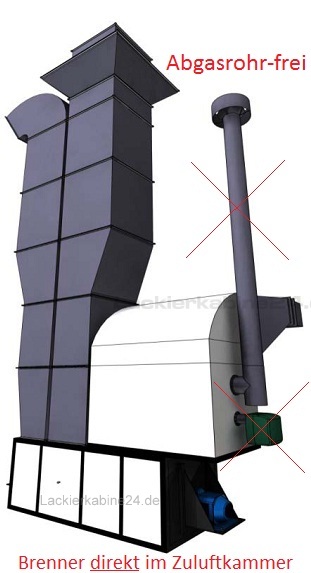

Comparison heating technology

Indirect blower burner

Oil / Gas operated

Indirectly in the heat boiler / heat exchanger

Installed with chimney

Direct gas surface burner

Only with gas (natural gas or liquefied gas, no difference)

Saves approx. 25% heating energy and is fast

Without chimney , approx. 1500 € cost savings

Easiest cost-effective maintenance

With many monitoring compensators extra safe

Aluminum cross-current heat exchanger

Drying is carried out in the circulating air function, but during painting, the heated air is dissipated 100% outwards.

With an integrated cube of aluminium plates between exhaust air supply air, the already heated up-and-away heat for heating the cold supply air with approx. 50% efficiency.

Fans / turbines with enormous air power

32,000 m3 / hr

Reverse curved, easy maintenance and great performance, quiet

0.3 m/sec Air sink speed is mandatory !

No wedge belt with forward curved fans Short life, noisy, difficult maintenance

Wedge belt drive, forward curved

Very tedious maintenance, which is why it is also neglected

Lighting

LED strips with 1000 lux /m2

We always deliver turnkey !

Also extended 3J warranty and service optional

Configuration - Manufacturing - Sales - Accessories

Our company mainly deals with new painting systems !

our Engineering companies headquartered in Lörrach, it specialises in the design of painting systems.

We accompany you from the first idea and deliver your standard / individual painting booth.

High quality German and European production According to standards CE EN 13355:2004+A1:2009

Combination painting and drying system

+++ EU Quality + World Quality + German TÜV Quality

+++ All components (motors, electrical components...) German or European goods with service throughout Germany

+ Own service on site with warehouse Take advantage of the convenient opportunity now! Only for a short time...

One of the most outstanding painting systems in the world! Why? --> see special features at the bottom left ..... completely TÜV certified..... Plant 100% according to EC guidelines and standards Guaranteed 100% CELIBER European production with the highest quality components

In the list of recommendations of Mercedes-Benz, Renault, Ford and others

Plant for best results, with high-tech turbines and very high quality equipment water-based paint and other varnishes look at and convince yourself ! Who dares and asks wins!

Space requirement when units on the side: width 600 x height 360 to 420 cm rear: length 860cm

Air outputs with high-performance turbines directly (therefore low energy loss):

Exhaust air 28000m3/h, supply air 28000m3/h NET VALUES !

Full rusting

Ideal air flow through 19° angled walls

10 programs with touchscreen control preset and individual programs for vers. Water-based paints (no cheap touchscreen with 1 program or without pressure control)

High-tech control cabinet

Metal pre-filter, very effective,

no maintenance costs of direct gas surface burners 300kW * (or indirect gas/oil burner)

100% gas output, saves real money and is super fast, without gas odour in the cabin, no extra chimney pipe needed

Must-read: Features of a qualitative painting system Automatic pressure control and monitoring, frequency converter (saving mode)

The quality of the insulation walls is certified!

Stone wool (no cheap mineral wool) escape door, side heat recovery by circulating air

Net price plus Ges. VAT Installation and delivery costs by arrangement. (now also cheap!)

Car truck painting booths

Car truck painting booths