Powder coating color change made easy

Slim design

Fast cleaning

Smooth and effective powder distribution

Brilliant Coating Performance

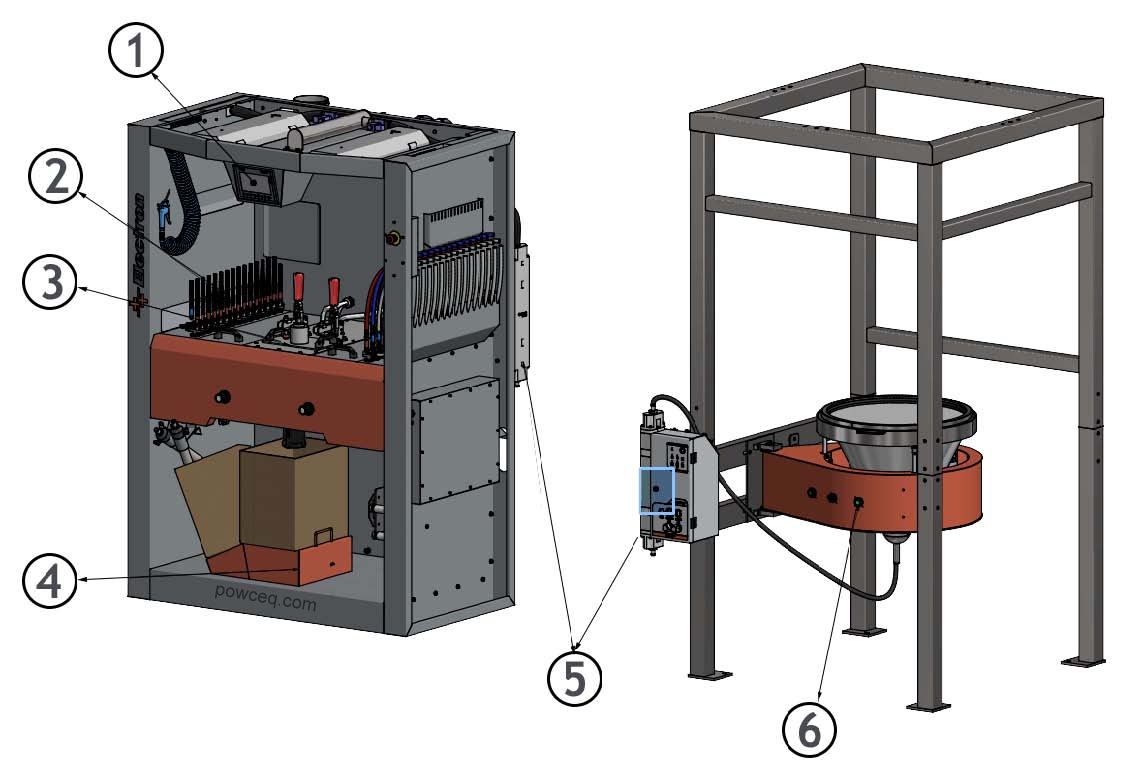

PM1 - Adaptable to any system

Semi-automatic cleaning system

(only gun hose cleaning automatic)

Big fixed powder container

Suitable for few color change in a day

Adaptable to any other system

Up to 30 injectors or 24 pumps + feed

Color change in 20 min.

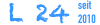

PM2 - Few Colors

Injectors drive out, easy to clean together

Up to 30 injectors + feed

Multiple plastic containers for each color

Transferpumps

Excellent powder delivery of 8kg/min

With cart and lance

We offer complete automatic coating solutions !

- Pretreatment line

- Automatic washing

- Powder booths

- Manual or automatic spray guns

- Conveyor systems

What is powder center good for?

At a powder coating center, you can expect to find state-of-the-art equipment and experienced technicians who are skilled in the art of powder coating. These centers often offer a range of services, including surface preparation, powder application, and curing. Some centers may also offer additional services such as sandblasting or chemical stripping to help prepare surfaces for coating.

One of the key benefits of using a powder coating center is the ability to achieve fast and reliable color changes. Many centers are equipped with advanced technology that allows for a high degree of automation and dust-free operation. This means that you can achieve consistent, high-quality results with minimal downtime.

In addition to offering fast color changes, many powder coating centers are also equipped with sensors for data acquisition. This allows you to receive statistics on various production data, such as powder consumption. By monitoring this data, you can optimize your processes and improve efficiency.

Another advantage of using a powder coating center is the ability to achieve a high level of coating quality. Many centers use powerful powder injectors and high-quality powder preparation techniques to ensure a consistent, homogeneous powder feed. This results in a smooth, even finish that is resistant to chipping and scratching.

Overall, using a powder coating center can help you achieve high-quality results while improving efficiency and reducing downtime. Whether you are looking to coat large industrial components or small consumer goods, a powder coating center can provide the expertise and equipment you need to get the job done right.

Here are some advantages of using a powder coating center:

State-of-the-art equipment: Powder coating centers are equipped with the latest technology to ensure consistent, high-quality results.

Experienced technicians: Powder coating centers employ skilled technicians who are knowledgeable about the powder coating process and can help you achieve the desired finish.

Range of services: Many powder coating centers offer a range of services, including surface preparation, powder application, and curing.

Fast color changes: Advanced technology allows for fast and reliable color changes, reducing downtime and improving efficiency.

Dust-free operation: Many centers are designed for dust-free operation, ensuring a clean and safe working environment.

Data acquisition: Some centers are equipped with sensors that allow you to monitor production data, such as powder consumption, to optimize your processes.

High-quality results: Powder coating centers use advanced techniques to ensure a consistent, homogeneous powder feed, resulting in a smooth, even finish.

Durability: Powder coating produces a durable finish that is resistant to chipping, scratching, and fading.

Eco-friendly: Powder coating is an environmentally friendly process that produces minimal waste and does not release harmful chemicals into the air.

Cost-effective: Powder coating can be a cost-effective finishing option, especially for large production runs.

These are just some of the many advantages of using a powder coating center. By working with a reputable center, you can achieve high-quality results while improving efficiency and reducing costs.

Catalog Coating Feed

Catalog Coating Feed