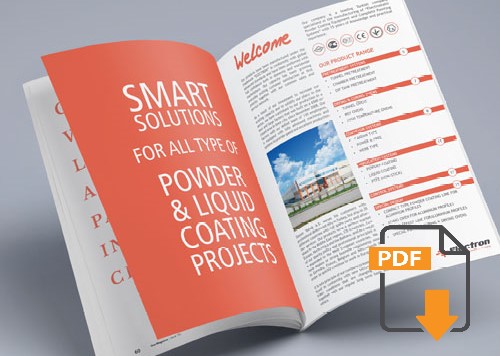

Convection powder oven

Loading over

- Trolley or

- Conveyor track / hanging rails

Catalog Powder Coating Equipment

Catalog Powder Coating Equipment

Heating :

Electrically or with gas / oil burner

Convection oven, several fans

Homogeneous air distribution (most important!)

Separating doors, sliding doors, folding doors on both sides

Rails, beams, all variants available.

Delivery time only 8 weeks!

Pre-assembled

Dimensions inside

Usable area in meters

| Type | A width | B height | C depth |

|---|---|---|---|

| EL10 | 1 | 1 | 1 |

| EL12 | 1 | 1,2 | 1,5 |

| EL15 | 1,2 | 1,5 | 1,5 |

| EL20 | 1,5m | 1,8m | 2 |

| EL25 | 1,5m | 1,8m | 2,5 |

| EL30 | 1,5m | 1,8m | 3 |

| EL40 | 1,5m | 1,8m | 4 |

| EL50 | 1,5m | 1,8m | 5 |

| EL60 | 1,5m | 1,8m | 6 |

| EL70 | 1,5m | 1,8m | 7m |

Or ask for your desired size!

e.g. inside 7 x 2.5 x 3 m

Up to 200 ° C or 450 ° C

Powder coating is a popular finishing technique that involves applying a dry powder to a surface and then curing it using heat. The curing process is an essential step in achieving a smooth, durable, and long-lasting finish. During this process, the powder coating is heated to a specific temperature, causing it to melt and flow over the surface of the part. As the coating cools, it hardens into a tough, protective layer.

Curing ovens are used to heat cure parts after they have been coated with powder. These ovens come in various sizes and can be powered by electricity or gas. The size of the oven needed will depend on the size of the parts being coated and the volume of production. Smaller ovens are suitable for small- or medium-sized parts and can fit on a benchtop or in a shop corner. Larger ovens are available for industrial-scale production.

The temperature and duration of the curing process will vary depending on the type of powder coating being used. Most powders require a curing temperature of between 350°F and 400°F and a curing time of 10 to 20 minutes. However, some powders may require higher temperatures or longer curing times. It is important to follow the manufacturer’s instructions to achieve the best results.

Control: analog or digital

In addition to curing ovens, there are other types of equipment that can be used to cure powder coatings. Infrared lamps can be used to heat cure small parts or touch up larger parts that have been cured in an oven. These lamps emit infrared radiation, which is absorbed by the powder coating, causing it to melt and flow.

Overall, curing ovens play an essential role in the powder coating process. They provide the heat needed to cure the coating, resulting in a smooth, durable, and long-lasting finish. Whether you are a DIYer or a professional, there is a curing oven available to meet your needs.

Some variations of kiln curing

The smallest - 1.1m

For 6x rims

Within 7 x 1.5 x 1.8 m

4m rear heating register

4m side view

Double doors

For trolleys

With dividing doors

Larger and special construction powder furnaces

5x rails

Semi-car. Conveyor system

Heavy parts

Conveyor ovens

4m special construction / rack trolley

Chain conveyor / sliding doors

Electrically heated

Continuous furnace

Traverses as desired, manually or semi-automatically

We offer complete solutions from a single source! Turnkey