Which automated powder coating system?

Let us find the answer together with our full range of equipment.

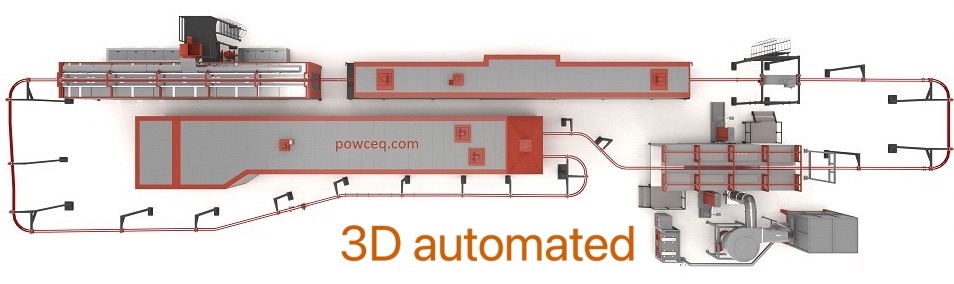

We deliver your 3D powder coating system:

State-of-the-art, efficient, turnkey.

Whether in New Zealand, South Africa or US...

The next Electron is probably a stone's throw away.

Distributors in 47 countries *2022

References all over the world in 83 countries

Product overview

See more videos

Complete solutions

From a single source coating line manufacturer

- Manual or automatic powder spray guns

- Control units

- Powder feed centers and pumps

- Powder booths

- Drying & curing ovens

- Pretreatment tunnels - automatic washing

- Special solutions

Spray and feeding

Manual coating guns

Corona ring + Quick cleaning

Automatic regulation PCC

- Perfect results with uniform layer thickness

- Quick change of operation with pre-programmable option settings

- User-friendly touchscreen panel

17 industrial models

Laboratory set with 5L container

Shop - Buy online now at promotional prices

Shop - Accessories & spare parts

Control systems

- Simple and understandable operation

- Data and history can be called up

- Energy saving functions

- Secure backup

- Remote maintenance

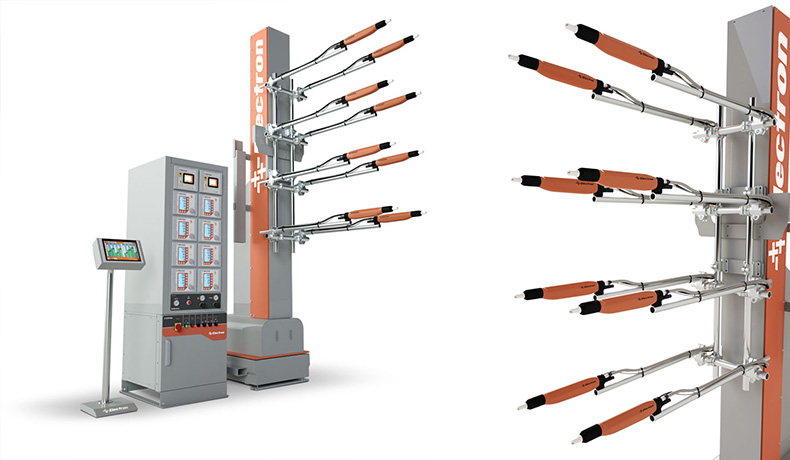

Automatic coating guns

Control units

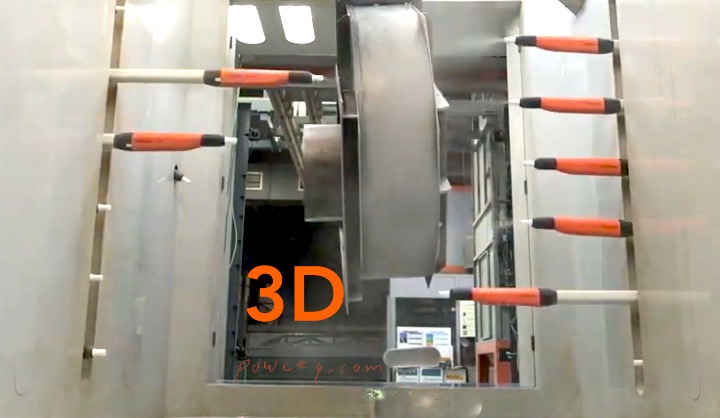

Reciporators

- PLC-controlled lifting devices

- Automatic selection of stroke and speed

- Perfectly synchronized with lifting devices

Feed center

3 main models - PM1, PM2 and PM3

Central powder feed container with powder pumps

Reduced powder consumption

Excellent powder delivery

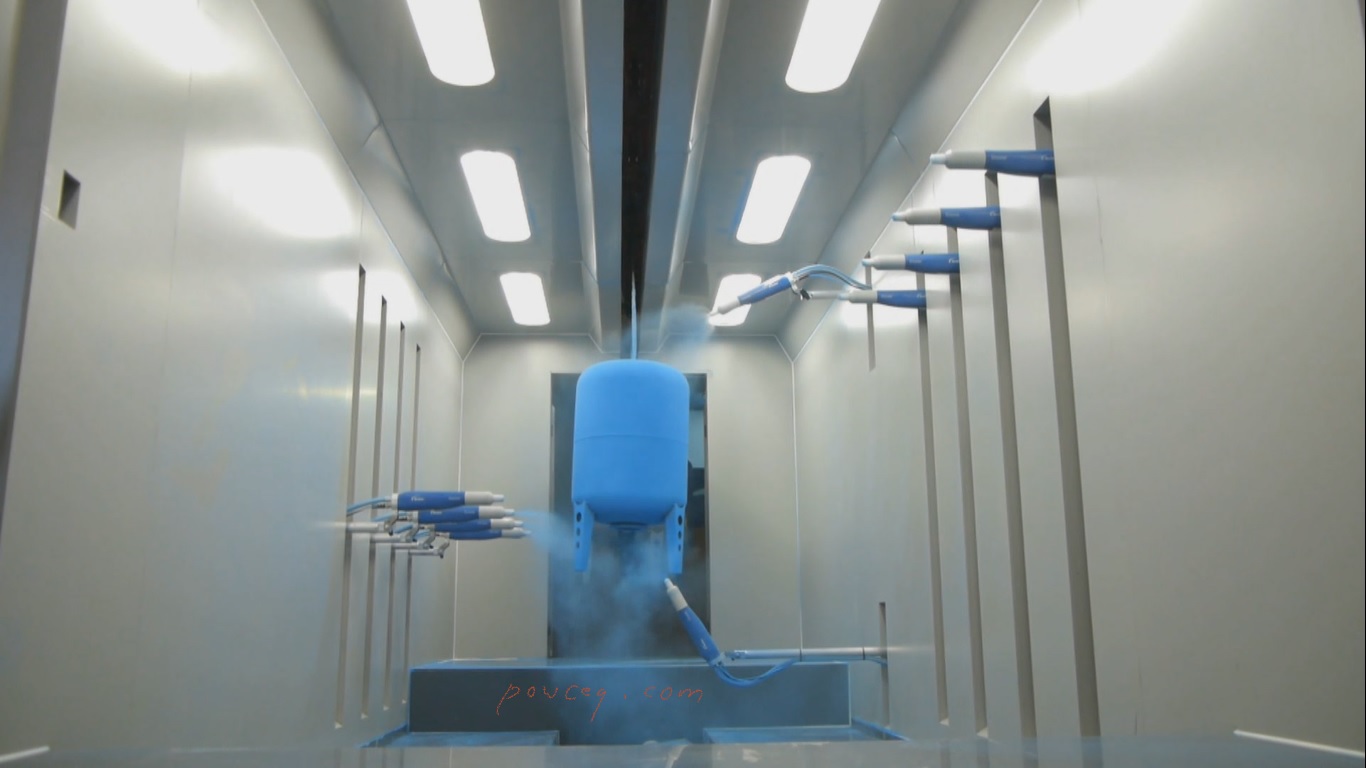

Powder Booths

Manual powder booth

Filter or recycling

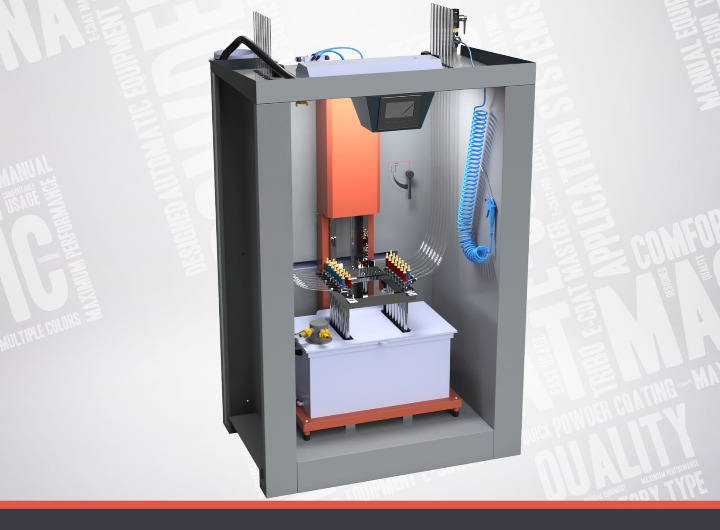

Complete systems for small parts

Spray wall

+ curing oven

+ coating devices

+ conveyor system

Automatic powder booth

- Cyclone or filter with recovery

- Made of plastic or steel

- Quick color change

- Low-noise fans

- Power & Free or Axial

- Automatic or manual

- Optimal solutions according to customer requirements

- High quality standards

Plastic cabins

Continuous spray washing systems

Pretreatment

• Nano technology (Oxsilan, phosphating

• Degreasing and pickling

• Iron and zinc phosphating lines

• Without chrome

• Spraying & immersion pretreatment lines

• Savings in chemical and water consumption

Powder curing ovens

- Subsidized or box-shaped designs

- Tunnel, U-Turn or special designs

- Energy-efficient and productive

- Perfect insulation and minimal heat loss

- Homogeneous air distribution

- Precise technology & intelligent solutions

Special dimensions and solutions

Box-Transfer

Manual conveyor systems

Design according to customer requirements

Semi-automatic cross platform